Description

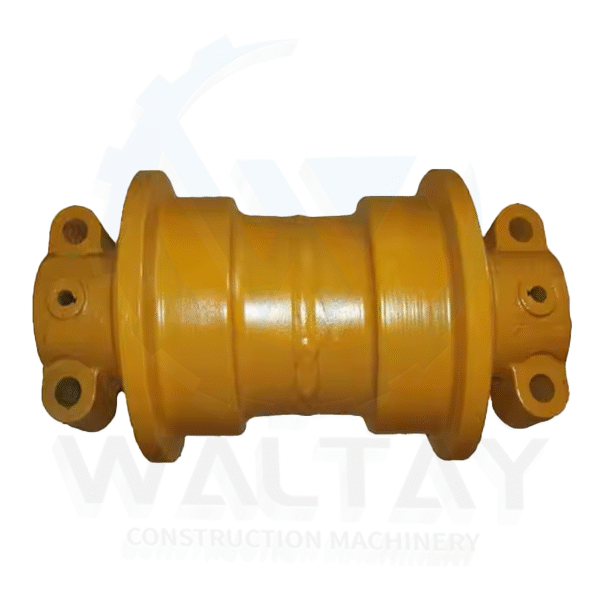

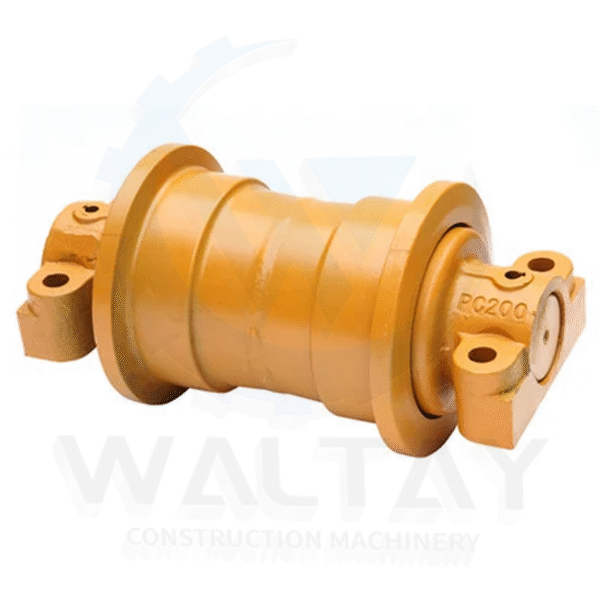

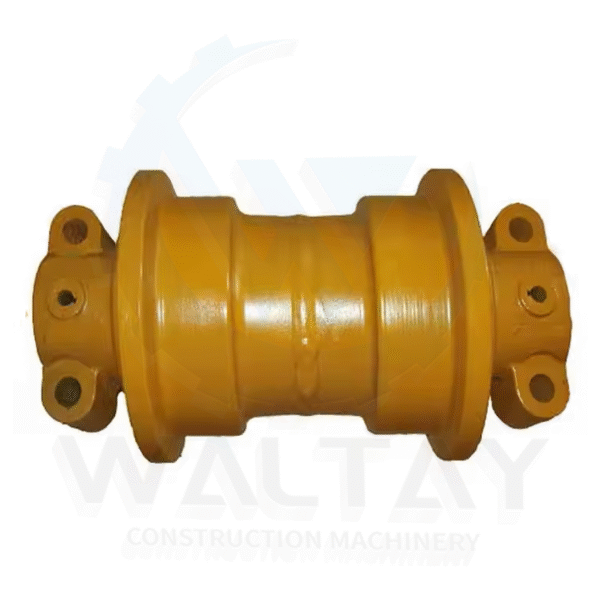

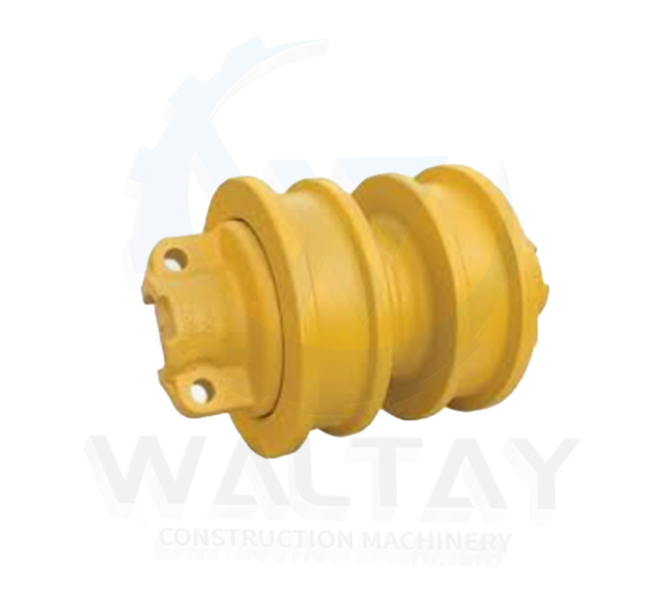

The Doosan DX60-7 Track Roller, part number 200104-00007B, also commonly known as a bottom roller or lower roller, is a vital cylindrical component of your mini excavator’s undercarriage system. Strategically positioned along the track frame, its primary functions are to support the weight of the machine, guide the track chain smoothly as it moves, and reduce friction between the track links and the track frame. By evenly distributing the excavator’s weight, the track roller helps prevent the machine from sinking into soft ground and absorbs shocks and vibrations encountered during operation, thereby protecting the overall undercarriage structure and enhancing operator comfort.

Manufactured to stringent OEM specifications, this track roller is typically constructed from high-strength alloy steel through advanced forging or casting techniques. Its running surface undergoes precise heat treatment, achieving a deep hardened depth and a surface hardness of HRC52-58, ensuring exceptional wear resistance and durability against abrasive conditions and heavy loads. The roller features robust seals and is lubricated for life, often being oil-filled, to prevent contamination from dirt, sand, and moisture while maintaining smooth, low-friction rotation. It incorporates reliable bearings (e.g., tapered roller bearings) to handle both radial and axial loads efficiently.

- OEM-Quality Part: Guarantees perfect fitment, uncompromised quality, and strict adherence to original factory performance specifications for the Doosan DX60-7 mini excavator.

- High-Strength Alloy Steel: Constructed from premium forged or cast steel for maximum durability and resistance to wear.

- Advanced Heat Treatment: Features a deep hardened surface (HRC52-58) for exceptional longevity in harsh operating environments.

- Sealed & Lubricated for Life: Equipped with heavy-duty seals and often oil-filled to ensure maintenance-free, smooth operation and prevent contamination.

- Precision Engineering: Designed to provide precise guidance and smooth rotation, reducing friction and stress on the track system.

Benefits:

- Optimizes Weight Distribution: Effectively supports the machine’s weight, improving stability and preventing sinking in soft terrain.

- Extends Undercarriage Lifespan: Reduces wear on track links, idlers, and sprockets by minimizing friction and ensuring proper track guidance.

- Enhances Machine Mobility: Facilitates smooth and efficient movement across various terrains, improving operational efficiency.

- Superior Durability: Built to withstand severe loads and abrasive conditions, ensuring long service intervals.

- Minimizes Downtime & Costs: High-quality construction reduces the frequency of replacements and prevents more extensive undercarriage damage.

Reviews

There are no reviews yet.