Description

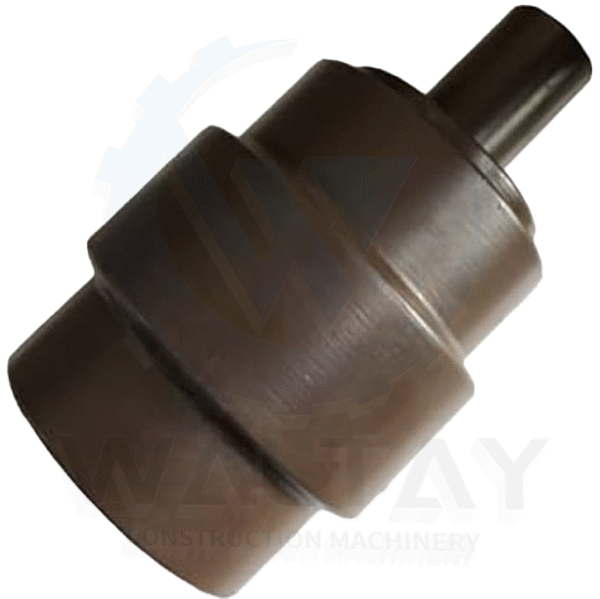

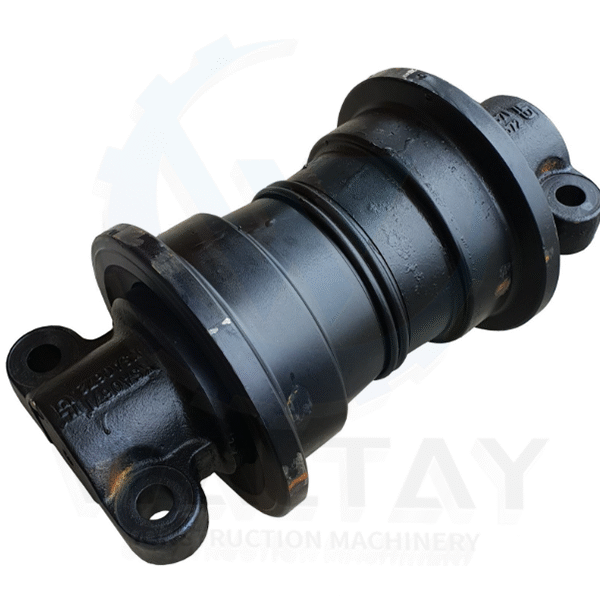

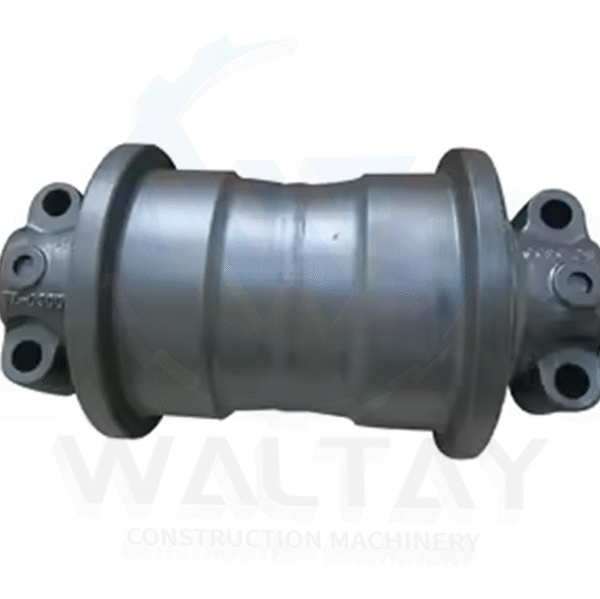

The Doosan DX255LC-7 Top Roller, part number 270-00064, also widely known as an upper roller or carrier roller, is an essential component of your excavator’s undercarriage system. Strategically positioned on the upper side of the track frame, its primary function is to support the weight of the track chain, preventing excessive sag between the idler and sprocket. This ensures the track maintains proper tension and alignment, allowing it to glide smoothly and efficiently, thereby reducing friction and wear on other costly undercarriage parts such as track links and idlers. This top roller is explicitly compatible with Doosan DX220, DX225LC (including -2, -3, and -5 variants), DX253, and DX255LC (including -3 and -5 variants) models. Given the typical design continuity in Doosan’s excavator series, this part is highly likely to be the correct fit for your DX255LC-7 as well.

Manufactured to stringent OEM standards, this top roller is typically constructed from high-strength, heat-treated alloy steel (e.g., 40Mn2 or 50Mn/40SiMnTi) to ensure maximum durability and exceptional resistance to wear and impact. Its robust design is built to withstand the continuous stress of supporting the track and the impacts from uneven terrain inherent in heavy excavation work. The roller features sealed shaft and bearings, which are pre-lubricated (often oil-filled) and protected by heavy-duty seals. This “sealed for life” design prevents the ingress of abrasive contaminants like dirt, mud, and water, which are common in excavation environments. This critical sealing mechanism ensures smooth, low-friction rotation and significantly extends the component’s operational lifespan by keeping internal parts clean and well-lubricated, reducing the need for frequent maintenance. The running surface is meticulously finished with a surface hardness typically ranging from HRC50-58, with a hardened depth of 5mm-12mm, providing optimal wear resistance.

A worn or failing top roller can lead to several operational issues, including excessive track slack, increased vibration, accelerated wear on track links, and potential de-tracking. These issues compromise machine stability, reduce operational efficiency, and can result in significant repair costs and unplanned downtime. Replacing a faulty top roller with a high-quality, OEM-standard part like the 270-00064 is vital for maintaining the integrity of your undercarriage system, ensuring consistent machine performance, and protecting your investment. This carrier roller is an indispensable replacement for routine maintenance or when addressing specific issues related to track support and guidance.

Key Features:

- OEM-Quality Part: Guarantees a precise fit and reliable performance, meeting or exceeding original factory specifications for Doosan DX255LC-7 and compatible heavy excavators.

- High-Strength Steel Construction: Fabricated from premium heat-treated alloy steel for maximum durability and robust resistance to wear and impact.

- Advanced Heat Treatment: Features a deeply hardened running surface (HRC50-58, depth 5-12mm typical) for exceptional longevity in challenging operating environments.

- Sealed & Lubricated Design: Features sealed shaft and heavy-duty bearings that are pre-lubricated for life, ensuring maintenance-free operation and superior protection against contaminants.

- Optimal Track Support: Engineered to effectively support the track chain, reducing sag and maintaining proper tension and alignment.

- Enhanced Longevity: Durable construction and advanced sealing contribute to an extended service life, even in harsh operating conditions.

Benefits:

- Ensures Smooth Track Movement: Facilitates continuous, low-friction operation of the track chain, improving overall machine efficiency.

- Reduces Component Wear: By maintaining proper track alignment and tension, it significantly minimizes wear on track links, sprockets, and idlers.

- Improves Machine Stability: Contributes to stable and controlled operation, reducing vibrations and enhancing operator comfort.

- Minimizes Downtime & Costs: High-quality construction and a sealed design reduce the likelihood of unexpected failures, helping to prevent extensive repairs and maximize operational uptime.

- Resistant to Contamination: Advanced sealing technology protects internal components from dirt, moisture, and debris, ensuring consistent performance.

Reviews

There are no reviews yet.