Description

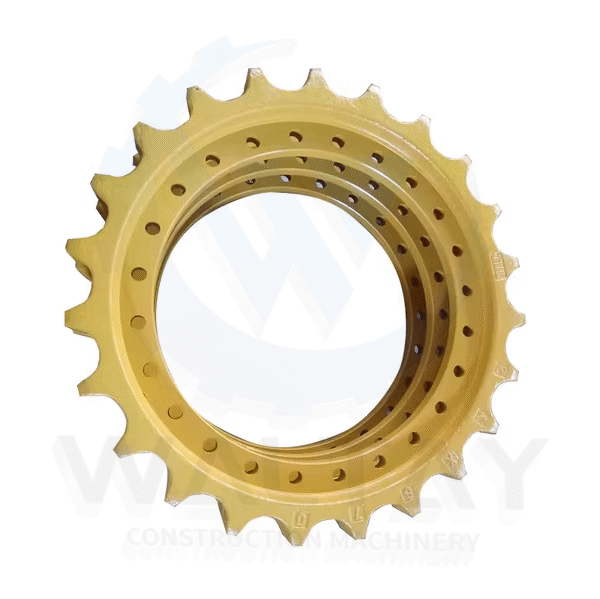

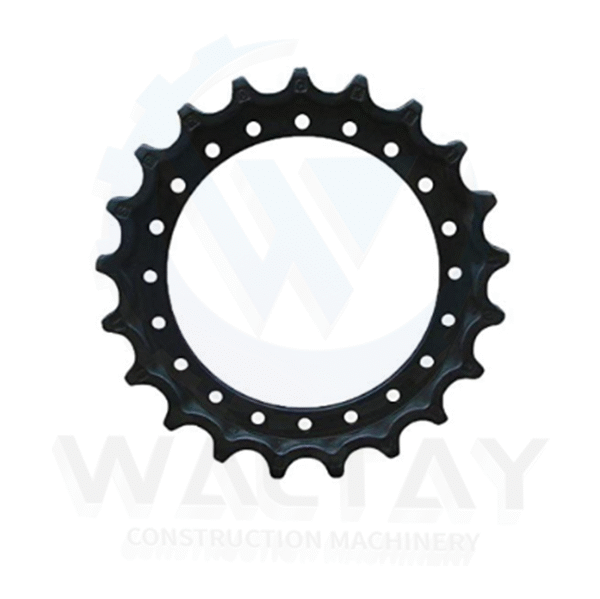

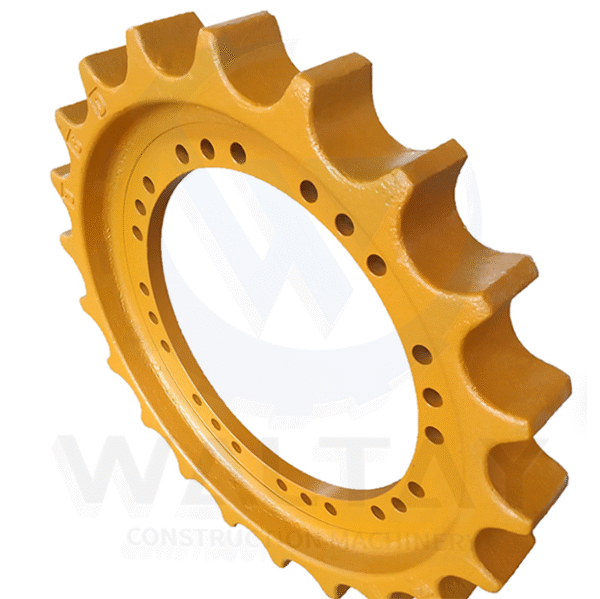

The Doosan Sprocket (or Drive Sprocket), part number 108-00022B, is a critical component of your excavator’s undercarriage and drivetrain system. This durable, toothed wheel is securely mounted on the final drive of the excavator. Its essential function is to engage directly with the track chain links, receiving rotational power from the machine’s hydraulic travel motor through the final drive and effectively propelling the excavator forward or backward. This precise and robust interaction with the track chain is paramount for efficient machine movement, optimal traction, and the overall longevity of your excavator’s track system.

This sprocket is confirmed to be compatible with a range of Doosan (and older Daewoo) excavators, including Doosan DX300LC, DX340LC, and S340LC-V. Given the direct lineage and shared undercarriage architecture common in Doosan’s excavator series, the 108-00022B sprocket is the correct and highly suitable component for your Doosan DX300LC-7 model, ensuring a precise fit and reliable performance that meets or exceeds original equipment manufacturer specifications.

Typically constructed from high-strength alloy steel (such as 35MnB), this sprocket undergoes rigorous manufacturing processes including forging or casting, and advanced heat treatment. The teeth are meticulously machined and surface-hardened (commonly to HRC52-58 with a hardened depth of 8mm-12mm) to maximize their resistance to abrasive wear and maintain optimal engagement with the track chain, even under the severe operating loads encountered during heavy excavation work. The robust construction ensures it can withstand the continuous stress of power transmission and the harsh impacts inherent in typical construction environments. While a specific weight for 108-00022B was not immediately available in the top search results, sprockets for this class of machine are substantial components, designed for durability.

A worn, broken, or improperly fitting sprocket can lead to a cascade of operational issues, including reduced traction, track slippage, accelerated and uneven wear on track links and idlers, and potential damage to the final drive system. These problems compromise the machine’s stability, reduce operational efficiency, and can result in costly repairs and unexpected downtime. Replacing a failing sprocket with a high-quality, OEM-standard part like the 108-00022B is crucial for maintaining the integrity and performance of your excavator’s undercarriage and drivetrain, ensuring smooth and reliable operation, and safeguarding your significant investment in the machine.

Key Features:

- OEM-Quality Part: Engineered to meet or exceed original factory specifications, ensuring precise fitment and reliable performance for Doosan DX300LC-7 and compatible models.

- High-Strength Alloy Steel Construction: Manufactured from premium, heavy-duty alloy steel (e.g., 35MnB) for maximum durability and robust resistance to wear and impact under heavy loads.

- Precision Heat-Treated Teeth: Features meticulously machined and surface-hardened teeth (HRC52-58 typical) for exceptional longevity, consistent engagement with the track chain, and extended service life.

- Optimal Power Transfer: Designed for efficient and reliable transmission of power from the final drive to the track, ensuring strong and consistent propulsion.

- Direct Compatibility: Confirmed for Doosan DX300LC, DX340LC, and highly suitable for the DX300LC-7.

Benefits:

- Ensures Smooth & Powerful Track Movement: Facilitates continuous, low-friction, and high-traction operation of the track chain, maximizing machine mobility and overall efficiency.

- Extends Undercarriage Lifespan: Precise tooth engagement minimizes abrasive wear on track links, idlers, and other critical undercarriage components, saving on future repair costs.

- Enhances Traction & Control: Provides reliable grip and power delivery, improving machine stability and operational control, especially in challenging or slippery terrain.

- Superior Durability: Built to withstand the extreme stresses and demands of heavy excavation work, offering long service intervals and reducing the need for frequent replacements.

- Minimizes Downtime & Costly Repairs: High-quality construction prevents premature failure, safeguarding your investment and maximizing operational uptime, allowing your machine to stay productive.

Reviews

There are no reviews yet.