Description

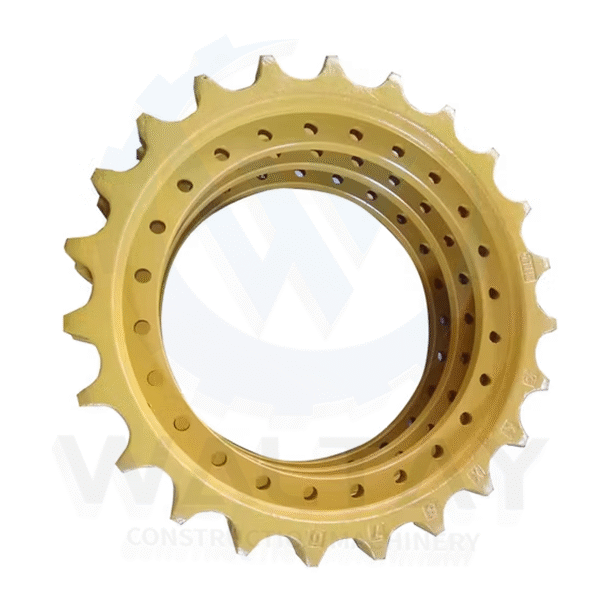

The Doosan Sprocket / Rim, part number 2108-1040A, is a crucial component of your excavator’s undercarriage and drivetrain system. As a key part of the track drive, the sprocket’s primary function is to engage with the track chain, receiving power from the final drive and propelling the excavator. This direct power transfer makes the sprocket essential for the machine’s movement and overall performance. This sprocket is specifically compatible with the Doosan DX140LC series, including the DX140LC-7.

Manufactured to stringent OEM standards, this sprocket is typically constructed from high-strength, heat-treated alloy steel to ensure maximum durability and exceptional resistance to wear and tear. Its robust design is built to withstand the continuous stress of transmitting power to the track and the impacts from uneven terrain. The sprocket features precisely machined teeth that accurately engage with the track chain links, minimizing wear on both components and ensuring efficient power transfer.

A worn or damaged sprocket can lead to several operational issues, including reduced traction, slippage, uneven track wear, and potential damage to the final drive. These issues compromise machine mobility, reduce operational efficiency, and can result in significant repair costs and unplanned downtime. Replacing a faulty sprocket with a high-quality, OEM-standard part like the 2108-1040A is vital for maintaining the integrity of your undercarriage and drivetrain system, ensuring consistent machine performance, and protecting your investment.

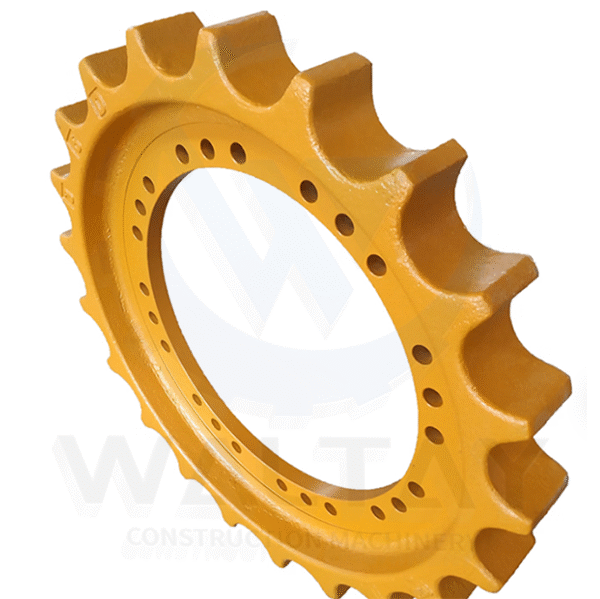

Key Features:

- OEM-Quality Part: Guarantees a precise fit and reliable performance, meeting or exceeding original factory specifications for Doosan DX140LC-7 excavators.

- High-Strength Steel Construction: Fabricated from premium heat-treated alloy steel for maximum durability and robust resistance to wear and impact.

- Precision-Machined Teeth: Ensures accurate engagement with the track chain, minimizing wear and maximizing power transfer efficiency.

- Optimal Power Transmission: Engineered to effectively transfer power from the final drive to the track chain, providing reliable propulsion.

- Enhanced Longevity: Durable construction contributes to an extended service life, even in harsh operating conditions.

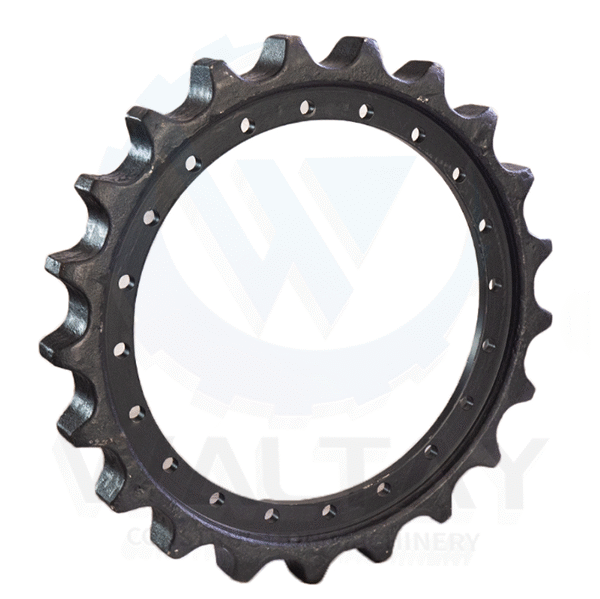

Benefits:

- Ensures Efficient Track Movement: Facilitates continuous, reliable operation of the track chain, improving overall machine efficiency.

- Reduces Component Wear: By providing precise engagement with the track chain, it significantly minimizes wear on the track links and final drive.

- Improves Machine Traction: Contributes to stable and controlled operation, particularly in challenging terrain.

- Minimizes Downtime & Costs: High-quality construction reduces the likelihood of unexpected failures, helping to prevent extensive repairs and maximize operational uptime.

- Resistant to Harsh Conditions: Built to withstand the demanding conditions of excavation environments.

Reviews

There are no reviews yet.