Description

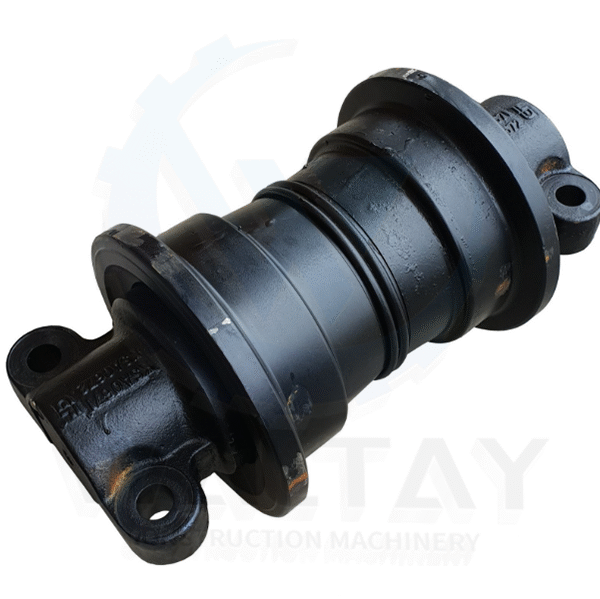

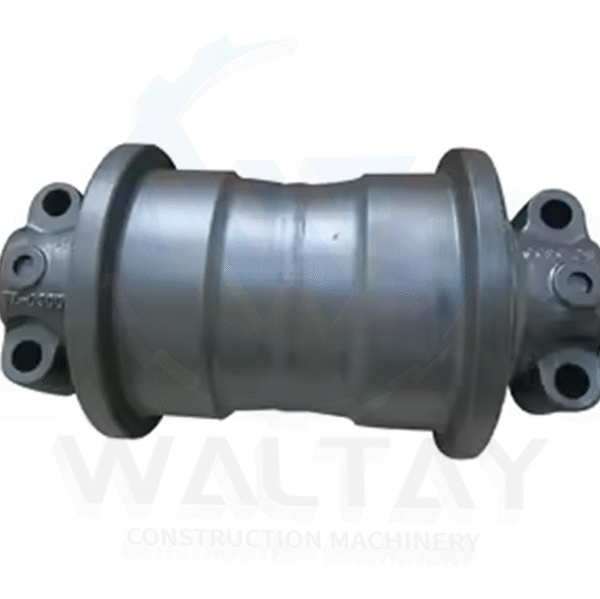

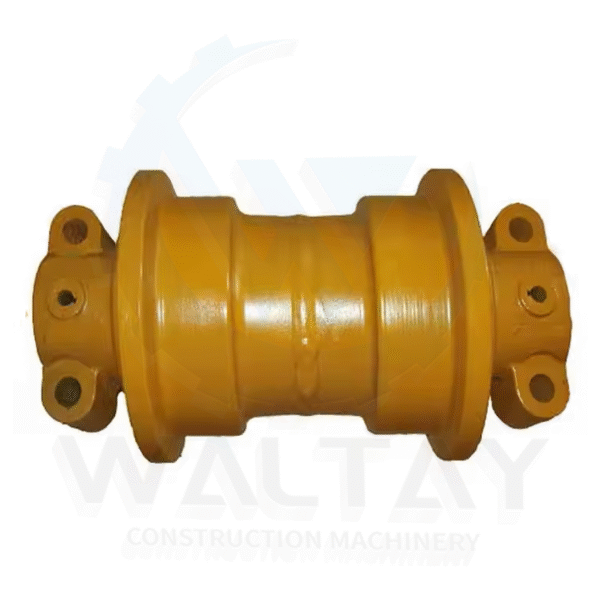

The Doosan DX225LC-7 Track Roller, part number K1000976A, also widely recognized as a bottom roller or lower roller, is an indispensable component of your excavator’s undercarriage system. Positioned strategically along the track frame, its primary role is to bear the substantial weight of the machine, facilitate smooth movement of the track chain, and minimize friction as the track links traverse. This even distribution of weight not only enhances the excavator’s stability, preventing it from sinking into soft ground, but also absorbs shocks and vibrations encountered during operation, thereby safeguarding the entire undercarriage structure and improving operator comfort.

This track roller is manufactured to stringent OEM specifications, typically from high-strength alloy steel, such as 35MnB, using advanced forging or casting processes. Its running surface undergoes precise heat treatment, achieving a deep hardened depth of 8-12mm and a surface hardness of HRC52-58. This meticulous process ensures exceptional wear resistance and longevity, even under abrasive conditions and heavy operational loads. Weighing approximately 38 kg, the roller is designed to be sealed and lubricated for life, often filled with oil, which effectively prevents the ingress of contaminants like dirt, sand, and moisture, while ensuring consistent, low-friction rotation. It incorporates durable bearings (e.g., tapered roller bearings) engineered to efficiently manage both radial and axial forces.

The integrity of track rollers is critical for overall excavator health. Worn or damaged rollers can lead to various operational problems, including increased friction, accelerated wear on other undercarriage components like track links and sprockets, reduced machine stability, and a higher risk of track de-tracking. Given that these components often operate in challenging environments exposed to mud, water, ash, and strong impacts, their wear resistance and the reliability of their bearing seals are paramount. Replacing compromised rollers with high-quality, OEM-standard parts like the K1000976A is essential for restoring optimal machine mobility, maintaining track system integrity, safeguarding your significant undercarriage investment, and minimizing costly unplanned downtime. This track roller is an ideal replacement part for both routine maintenance and addressing performance issues stemming from undercarriage wear.

Key Features:

- OEM-Standard Quality: Ensures a perfect fit and performance equivalent to original factory specifications for Doosan DX225LC-7 excavators.

- High-Strength Alloy Steel Construction: Made from premium forged or cast alloy steel (e.g., 35MnB) for maximum durability and resistance to wear and impact.

- Advanced Heat Treatment: Features a deeply hardened running surface (HRC52-58, depth 8-12mm) for exceptional longevity in demanding conditions.

- Sealed & Lubricated for Life: Equipped with heavy-duty seals and factory-filled lubrication (often oil-filled) to provide maintenance-free, smooth operation and prevent contamination.

- Precision Engineering: Designed for accurate track guidance and consistent rotation, reducing friction and stress across the entire track system.

Benefits:

- Optimizes Machine Stability: Efficiently supports the excavator’s weight, enhancing overall stability and preventing sinking in soft ground.

- Extends Undercarriage Lifespan: Reduces wear and tear on other vital undercarriage components, leading to a longer operational life for the entire system.

- Enhances Operational Efficiency: Ensures smooth track movement, contributing to better machine mobility and productivity on various terrains.

- Superior Durability: Built to withstand severe loads and abrasive environments, providing reliable service and reducing the frequency of replacements.

- Minimizes Downtime & Repair Costs: High-quality construction and robust design reduce the likelihood of unexpected failures, helping to prevent costly repairs and unplanned downtime.

Reviews

There are no reviews yet.